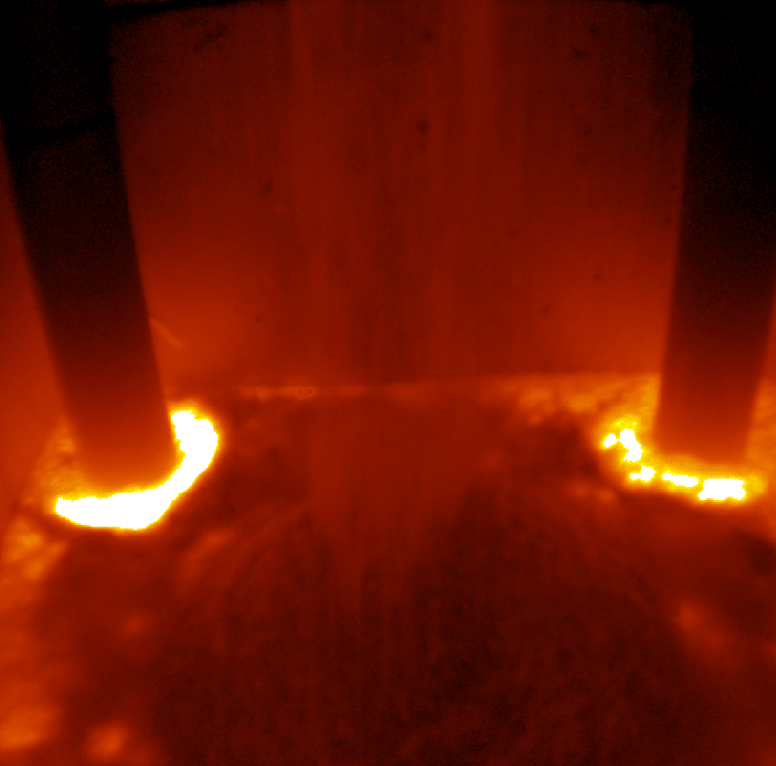

The GeoMelt® vitrification technology was developed in the early 1980’s by the Pacific Northwest National Laboratory (PNNL), for the U.S. Department of Energy (DOE). Today, VNS owns worldwide exclusive rights to this technology. GeoMelt® can be deployed in a number of ways including an in container version called GeoMelt® In Container Vitrification (ICV™). ICV™ is a batch waste treatment process that is performed in a single-use refractory container in which graphite electrodes are inserted. The waste is added with glass-formers reagents (if the waste does not contain sufficient glass formers) and melted using Joule heating when an electrical current is applied between the electrodes. The process starts with an initial batch of waste and reagents mixture. Feeding of waste material after the initial batch has melted allows for the container to be filled as the vitrification process continues and volume reduction occurs. Hazardous organics are destroyed by pyrolysis and most inorganic materials are incorporated into the glass matrix. The off-gases are collected and treated in a dedicated unit. Once the container is filled, power is shut off and the molten mixture cools into a homogenous glass monolith. In most applications, the ICV™ container serves as the disposal container. There is no pouring required nor concerns with refractory corrosion, which allows the process to be highly reliable while accommodating a wide range of waste chemistries and high waste loadings.

The final waste form is an inert, dense, mechanically stable glass. Radionuclides and hazardous metals are included into the glass structure, establishing strong chemical bonds with the glass network components. As a result, they are not preferentially leached even if the glass monolith is broken or size reduced.

Since the introduction of GeoMelt®, more than 27,000 tons of contaminated soils and waste have been treated successfully in various countries including Japan, Australia, and the United States.

For specific wastes with limited disposition paths, Veolia performs technology advancements to adapt GeoMelt® to the specific needs of these new waste streams. An example of this is for treatment of reactive metal containing waste and other problematic legacy waste or large dimension waste.

This work has been carried out at different scales from laboratory work to industrial plants.

Our presentation shows a description of the Geomelt® ICV™ technology and gives an overview of the different pilot and industrial Geomelt installations available around the world, including the latest developments.