In this presentation, we will explore advantages, benefits and usefulness of numerical modeling which has become an indispensable tool for designing, optimizing, and controlling industrial processes. Glass manufacturing is no exception, and numerical modeling of glass furnaces has thus been gaining increasing importance over past few decades.

Glass melting furnaces are a crucial component of the glass manufacturing process and are subject to a variety of complex physical and chemical processes. Associated challenges, such as high temperatures or maintaining precise control over the glass melting process, contribute to a vital need for mathematical models which can help to better understand the process as well as to predict furnace behavior under different conditions. This then leads to improved efficiency, reduced costs, and better product quality.

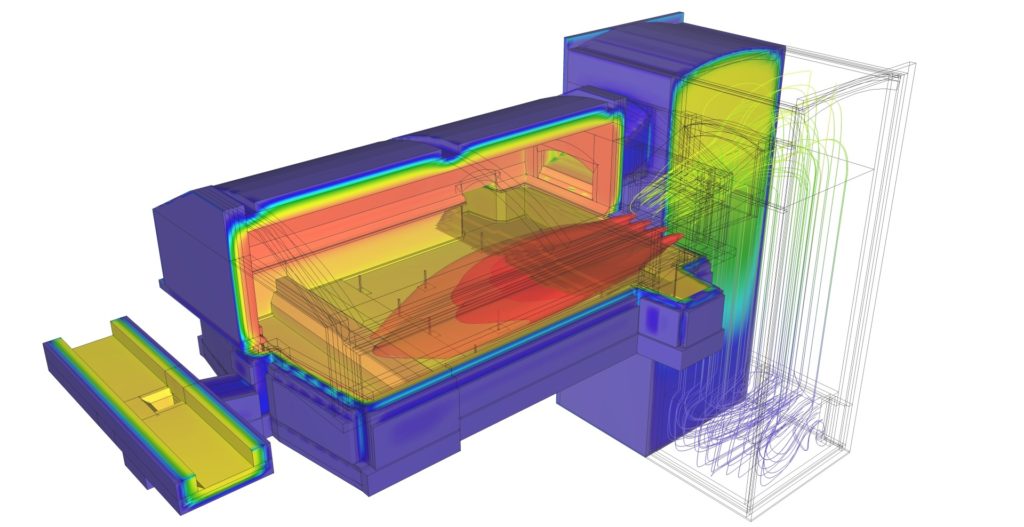

Firstly, ability of numerical modeling to understand complex physical and chemical phenomena that occur inside the furnace will be demonstrated. This understanding enables furnace design optimizations, controlling process variables, and improving quality of produced glass. Furthermore, numerical modeling can help reducing energy consumption and emissions, which is not only economically advantageous, but also environmentally responsible.

Secondly, advantages of numerical modeling’s flexibility will be discussed. Numerical models can simulate different scenarios, such as changes in furnace geometry, fuel type, or raw material composition. This flexibility allows furnace operators to predict and mitigate potential problems before they occur, and to optimize the process for various operating conditions.

Finally, challenges associated with developing and implementing mathematical models for glass melting furnaces, including the need to collect accurate data and limitations of current modeling techniques, will be explained.

In conclusion, numerical modeling is a powerful and valuable tool for understanding and optimizing glass melting furnaces, leading to saving energy, improving glass quality, and reducing emissions. With an increasing demand for sustainable manufacturing practices, numerical modeling will continue to play a crucial role in the glass manufacturing industry, both for manufacturers and consumers of glass products.