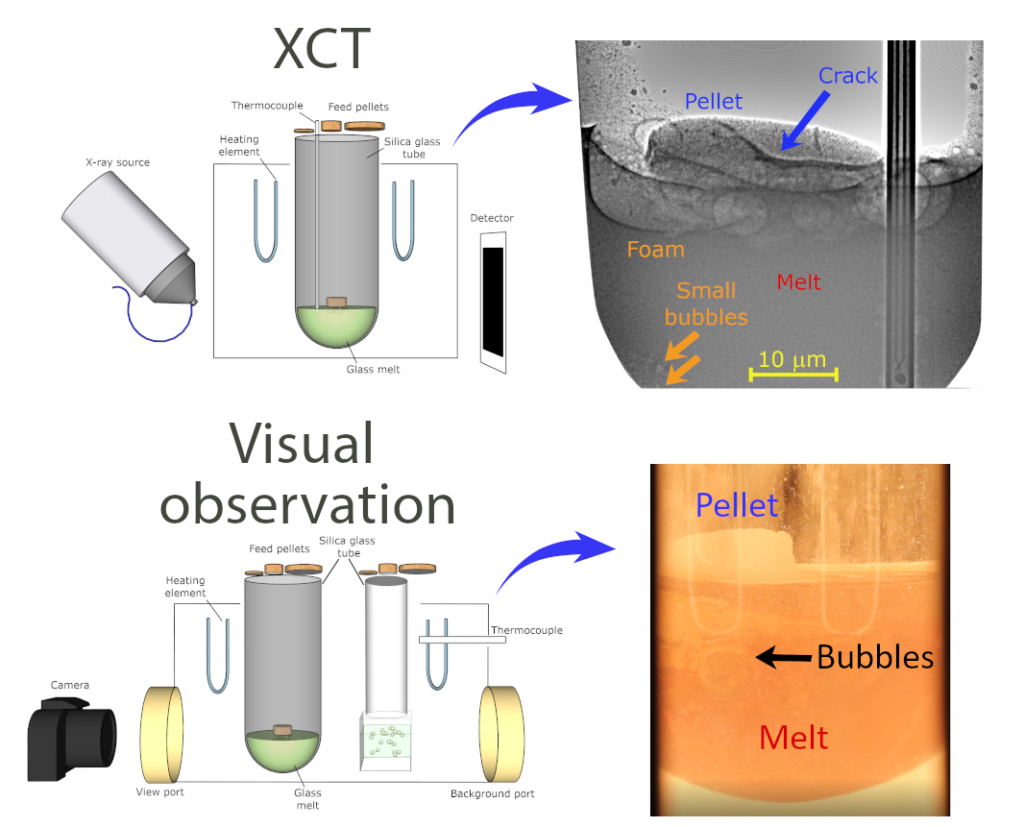

High-temperature visual observation of glass melting has been used for decades to understand processes that occur during glass production and to improve the overall process efficiency. Because of its simplicity, visual observations are broadly used to investigate bubble nucleation, fining, or refractory corrosion. For both commercial glassmaking and nuclear waste vitrification, visual observations provide a cost-effective method to study the influence of composition and makeup of commercial glass batches and waste glass melter feeds on the conversion process and the phenomena that influence the rate of glass production. We present an overview of experimental configurations used to elucidate aspects of batch-to-glass conversion with specific focus on foaming. This includes the feed expansion test (FET), a method that provide insight into the modes of foam growth and collapse in heated glass batch samples, X-ray computed tomography (XCT), and evolved gas analysis (EGA). However, understanding dynamics of the foam layer at the bottom of the batch blanket requires other experimental methods to be employed. We are in the process of developing an observation setup in which foam at the interface between the batch and molten glass is directly viewed and monitored. Overview of results obtained thus far on commercial batches and nuclear waste melter feeds will be presented.

Abstract

In-situ visual observations of glass melting processes

In-situ visual observations of glass melting processes

Jose Marcial*1, Miroslava Peterson 1, Richard Pokorny 2, Jaroslav Klouzek 2, Steven Luksic 1, Pavel Hrma3, Albert A Kruger4

1 Pacific Northwest National Laboratory, Richland, WA, 99352, USA

2 University of Chemistry and Technology Prague, Technicka 5/1905, 166 28, Prague 6, Czech Republic

3 AttainX, Support Services Contractor to the Office of River Protection, U.S. Department of Energy, Richland, WA, USA

4 U.S. Department of Energy, Office of River Protection, Richland, WA, 99352, USA

2 University of Chemistry and Technology Prague, Technicka 5/1905, 166 28, Prague 6, Czech Republic

3 AttainX, Support Services Contractor to the Office of River Protection, U.S. Department of Energy, Richland, WA, USA

4 U.S. Department of Energy, Office of River Protection, Richland, WA, 99352, USA

- Type: Guest oral presentation

- Related categories: New glasses for energy transition